Our infrared spectrometer offers an open and reliable solution for plastic analysis.

Ozirma is an open-source and low-cost sensor that identifies different types of plastic (PE, PVC, PET, PS, etc.), an essential first step in recycling. The goal is to facilitate local and autonomous recycling of plastic waste.

Large industrial recycling centers already use infrared spectroscopy to sort plastic waste.

Small plastic waste recovery workshops do not have the budget for this kind of proprietary technology.

Ozirma is a sensor that finally democratizes access to infrared spectroscopy.

Beyond the engineering challenges (optics, mechanics, electronics) that it represents, Ozirma indeed meets fundamental socio-economic needs:

Only about 10% of plastic waste is currently recycled. Sorting used plastic is the essential first step in its recycling process.

Industrial recycling centers use a highly efficient sorting method based on very fast but very expensive infrared spectrometers (over €100,000).

In recent years, several projects have emerged aiming to democratize plastic waste recovery techniques, such as Precious Plastic and Plastic Odyssey.

Small structures stemming from these movements use qualitative manual methods that do not efficiently sort all types of plastics. A low-cost sensor would allow these structures, as well as small workshops, fab labs, and makers, to better sort plastics and recycle more of them.

Although more affordable spectrometers have recently appeared, such as the Plastri at €25,000 or the Plastell at €3,500, there is currently no truly low-cost and open-source sensor for small-scale plastic sorting.

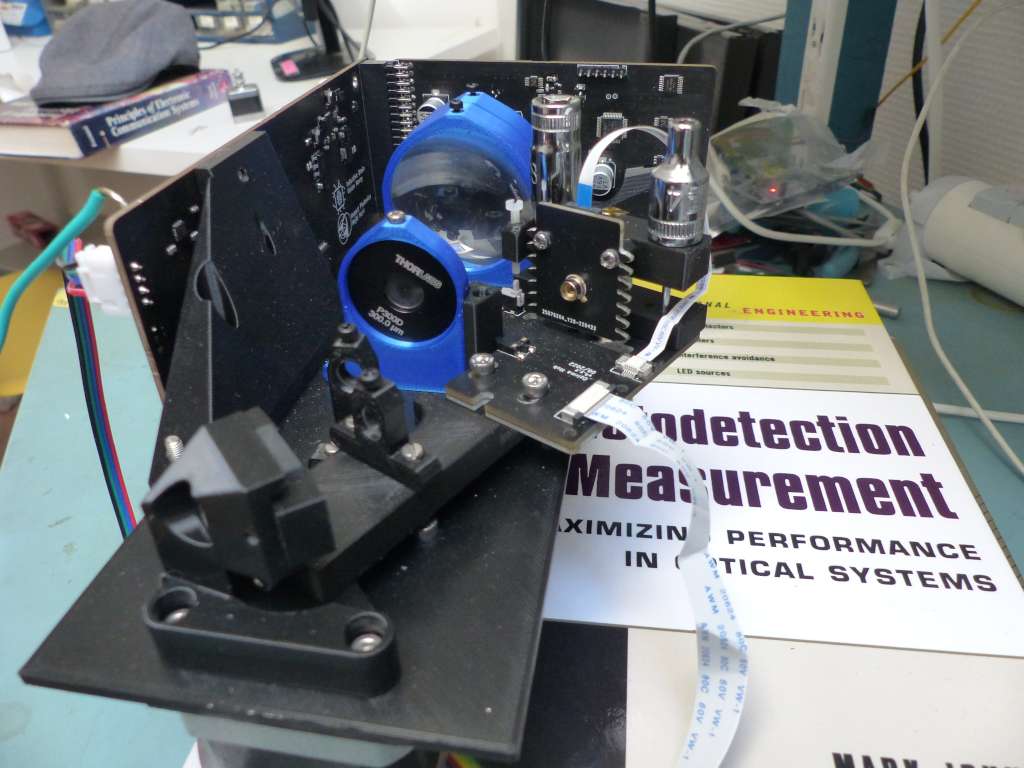

Ozirma is a small spectrometer that operates in the infrared range (900-1700nm). It measures diffuse reflection with a spectral resolution of 20nm. Its light source consists of four infrared LEDs (and a laser for alignment).

Its detector is a photodiode (a single pixel) that scans the spectrum by rotating around the diffraction grating (while compensating for alignment errors).

Ozirma is ultra low-cost (it only requires €300 in raw materials to build). It is also slower than existing solutions, due to the choice of using a single pixel and moving it. In the context of small recycling workshops, this is still acceptable.

However, this gives us the advantage of being able to measure the entire spectrum and, eventually, analyze other properties of plastics (additives, etc.).

For more technical details, you can visit Ozirma v2’s page on Hackaday: Ozirma v2 on Hackaday.

Since v2, the BOM has evolved, as we had to switch to a reflective diffraction grating with a gold coating and improve the photodiode’s compensation (vertical scan).

Mejdi and Vivien, two engineers with complementary technical expertise.

Mejdi is an engineer, maker, and entrepreneur. After studying physics and photonics, he founded a startup that developed a revolutionary spectrometer for blood analysis, with a very aggressive (and costly) patent strategy. Since then, Mejdi has shifted gears and turned towards open-source and the FabLabs community. He is now an expert in designing and prototyping scientific instruments that are both highly efficient and low-cost.

Vivien is an electronics engineer by training. He worked for three years at a company designing musical synthesizers, where he developed electronic systems. Shortly after founding his company Inductive Brain, he met Mejdi and decided to join this adventure. In the meantime, he also launched a bicycle trailer construction workshop.